This paper presents a new design for artificial intelligence in cyber-physical systems. We present a survey of principles, policies, design actions and key technologies for CPS, and discusses the state of art of the technology in a qualitative perspective. First, literature published between 2010 and 2021 is reviewed, and compared with the results of a qualitative empirical study that correlates world leading Industry 4.0 frameworks. Second, the study establishes the present and future techniques for increased automation in cyber-physical systems. We present the cybersecurity requirements as they are changing with the integration of artificial intelligence and internet of things in cyber-physical systems. The grounded theory methodology is applied for analysis and modelling the connections and interdependencies between edge components and automation in cyber-physical systems. In addition, the hierarchical cascading methodology is used in combination with the taxonomic classifications, to design a new integrated framework for future cyber-physical systems. The study looks at increased automation in cyber-physical systems from a technical and social level.

1 Introduction

Artificial intelligence (AI) and the Internet of Things (IoT) are the driving forces for industrial automation and the concept of smart factory. The industrial automation is shofting towards predictive maintenance and quality, human–robot integrations, and adaptive supply chains. While the industrial world is slowly getting used to the Industry 4.0 idea, the world is already evolving in the industry 5.0 (Sarfraz et al. 2021). This study reviews a juxtaposition of related systems and technologies, including IoT; Industrial Internet of Things (IIoT); Cyber-physical systems (CPS); and Industry 4.0 (I4.0). We briefly explain these related systems and technologies. The IIoT represents an evolved and connected distributed control system, using sensor, and other connected devices for data collection, exchange and analysis for improved productivity, energy management and other economic benefits (Boyes et al. 2018). The I4.0 is a generic designation for sets of strategic frameworks and initiatives, and a technical term to relate to new emerging digitalisation of business assets, processes and services. Different terms are used depending on the country, but all represent the same idea, which is ‘The Fourth Industrial Revolution’ (Carruthers 2016).

The IoT represents many different connected devices, using different connection protocols, performing data collection, for cloud storage, real-time analytics, among many other functions that create value (Nicolescu et al. 2018). On the other hand, the term CPS represents ‘smart’ systems that are built and depend on the interaction between physical and computational components (Craggs and Rashid 2017). CPS emerges from the interconnection of physical components in complex software to form new network and systems capabilities. While IoT focuses on interconnectivity, interoperability and integration of physical components in the Internet. Integration of IoT and CPS is what defined the IIoT and is expected to lead to developments of I4.0 in automation, real-time platforms, and automation guiding workers in production environment.

The research questions this study investigates are related to identifying the networked connection of people, processes, data, and things. The study is investigating the concepts that unites the cyber-physical world with the social aspects of the environment in which this technology is deployed. Also, a crucial question of interest for the study, is to review all available resources and identify the future cognitive makeup of I4.0. The terms ‘artificial intelligence’, ‘artificial cognition’, ‘cognition’, and ‘cognitive CPS’, in the context of this article are used interchangeably. These terms cohere to existing literature discussion on the effect from the evolving coupled systems and social networks in interconnected industrial systems. This article discusses major new initiatives in the industrial and manufacturing space in relation to privacy preserving and cyber risks in cyber-physical systems.

2 Cyber-physical systems in Industry 4.0

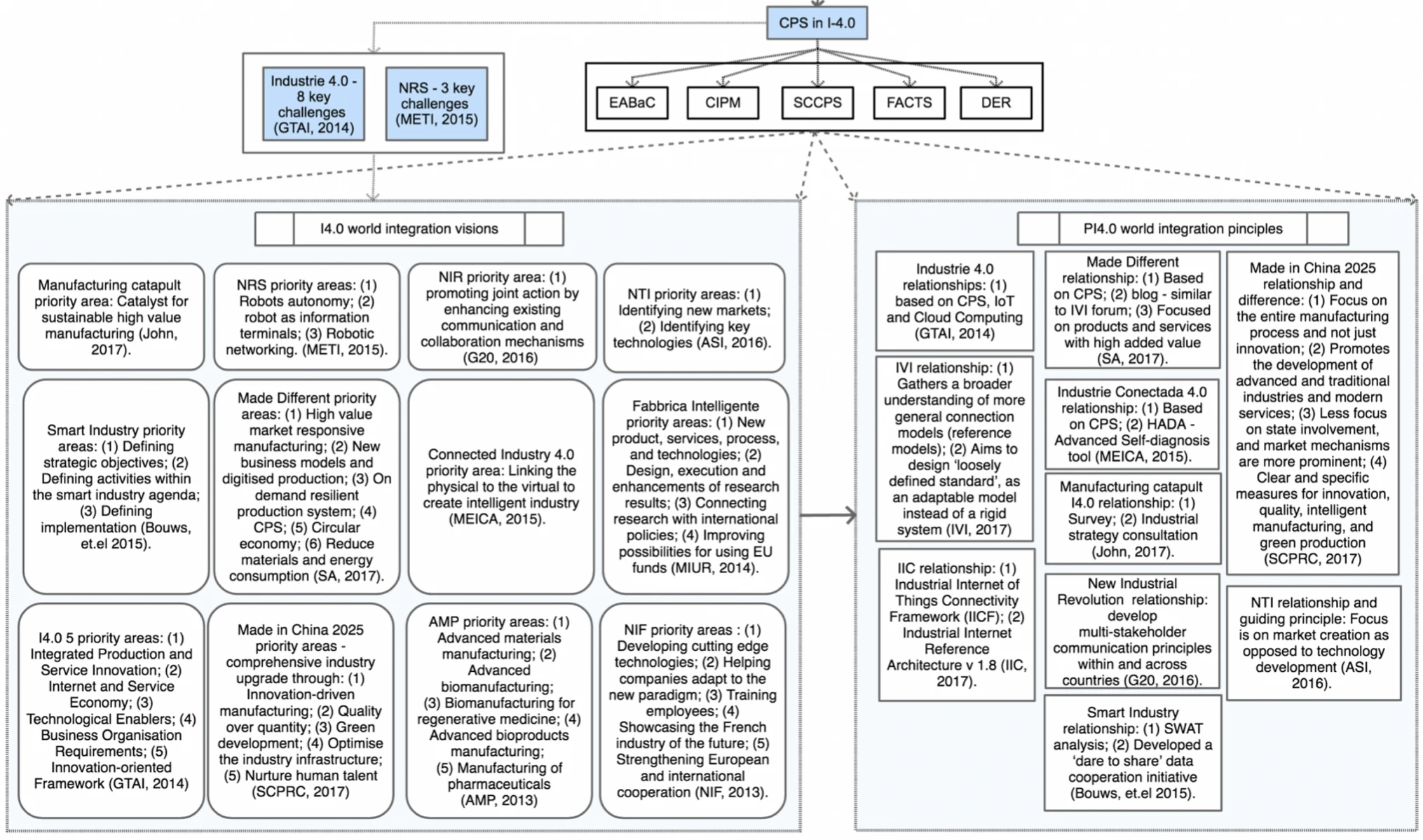

The engagement of AI in the cyber world and the human engagements in the physical world have been studied excessively in isolation, but the roadmap to I4.0 is still unclear (Caiado et al. 2021) and little attention has been given to the combination of AI and the cyber-physical world (Hollebeek et al. 2021). The world leading Industry 4.0 frameworks (Table 1)—identified from (Radanliev et al. 2020a, b, c, d, e) are analysed in a (a) comparative empirical study that correlates (b) hierarchical cascading based on the (c) grounded theory approach to determine (d) taxonomic classifications. A comparative empirical study (Murray-Rust et al. 2014; Van Kleek et al. 2018) is used to establish a design process (Lee et al. 2019a, 2019b) for integrating present CPS techniques and literature review for the future CPS techniques in Industry 4.0.

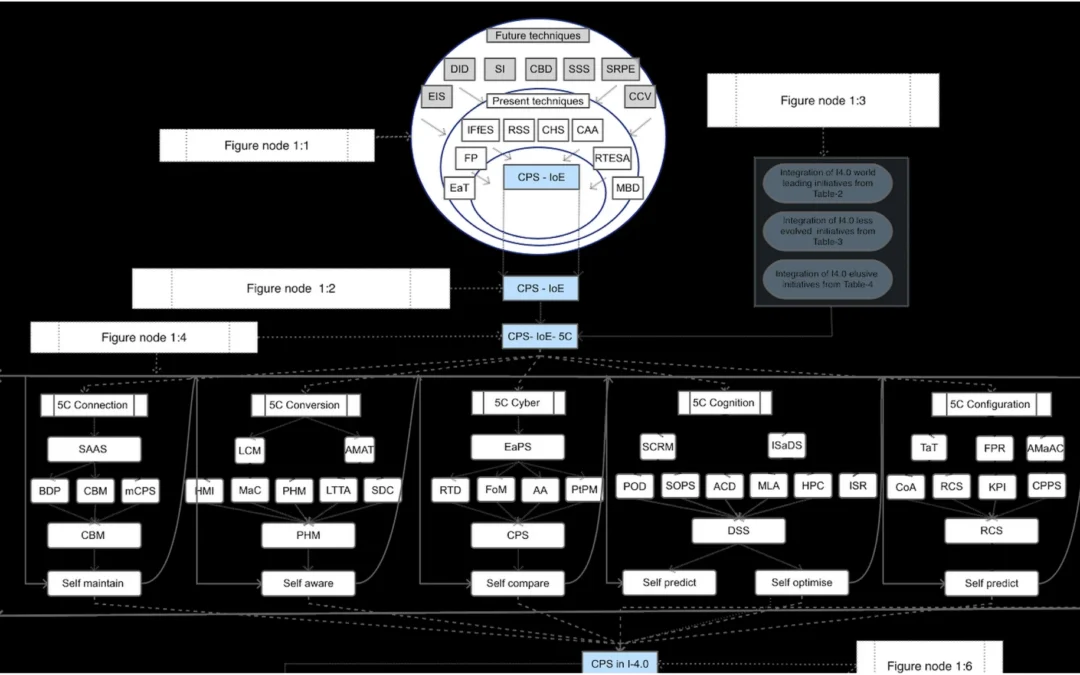

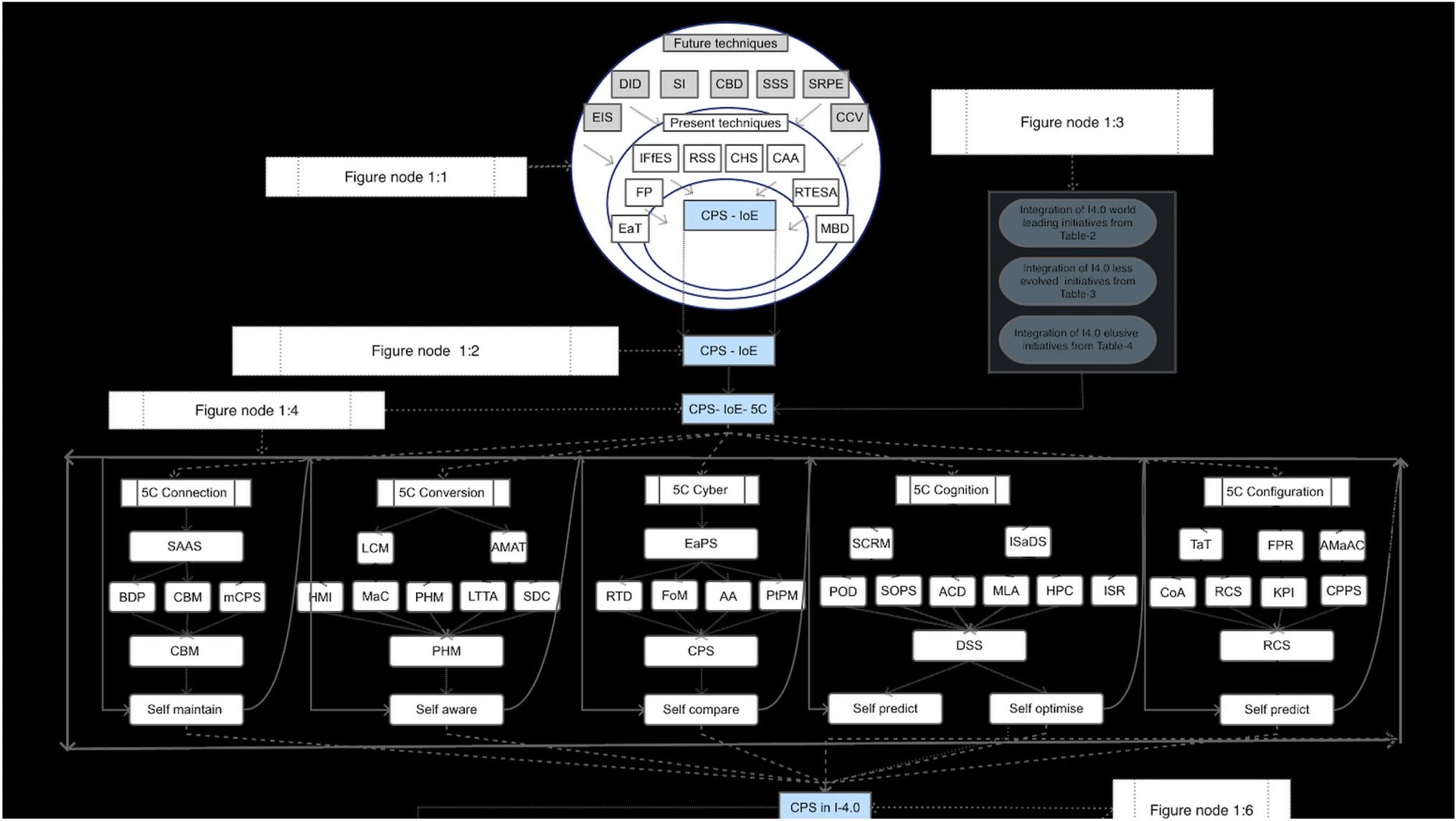

The results of the comparative empirical study on Industry 4.0 frameworks, are presented in detail in (Figure, Figure, and Figure) to determine the present and future mechanisms for artificial intelligence automation in cyber-physical systems. The complete findings of the comparative empirical study, correlated with hierarchical cascading of the taxonomic classifications from the grounded theory method, are presented in the Figure. The integrated framework in Figure compensates for shortcomings in each of the individual frameworks reviewed, calling for a standardised framework (Radanliev et al. 2020). For example, not all frameworks provide mechanisms for policy development.

Hence, our architecture (in Figs. 1 and 2) derives integrated recommendations and mechanisms that are directly related to increasing cognition in CPS. The methodology for designing our architecture (in Figs. 1 and 2) is related to from proof-of-concept (Wang et al, 2019), graph based visual analysis (Böhm et al. 2018), for ensuring data confidentiality (Zhang et al. 2018).

Fig.1 Architecture for future cyber-physical systems

Fig.2 Direction of the logical flow of cognitive CPS design

The architecture framework in Figure makes direct recommendations for elements of action, through integrating best practices from the empirical analysis. Figure integrates taxonomic grouping techniques (Figure node 1:1) from academic literature, to establish the CPS integration framework (in Figure node 1.2), with practical initiatives (in Figure node 1:3) from empirical studies data and consolidates these techniques with a cascading framework (in Figure node 1.4) that relates artificial intelligence with CPS technologies. A taxonomic grouping of future and present techniques is conceptualised with existing hierarchical cascading design (Radanliev 2016). By doing this, the leading initiatives are aggregated in integration areas. The integration framework in Figure follows taxonomic approach, in the formulation of encompassing principles for the integration across all initiatives (Figure node 1:3).

The argument of this process is that the integration of artificial cognition in CPS is not a selective process. Rather, it requires the synchronisation and harmonisation, which requires evaluation principles. The first stage of this study identified the related elements and principles from academic literature. These are grouped (from Figure nodes 1.1, to 1.4) and combined with present and future challenges from recent literature. To avoid duplication of abbreviations, the figure node 1:4 and the full list of abbreviations are borrowed from (Radanliev et al. 2020). The remaining Figure nodes emerge from this study. This presents the state-of-the-art in current understanding on the integration of artificial cognition in CPS. The arrows in Figs. 1 and 2, stand for the direction of the logical flow of cognitive CPS design.

In the second stage (Figure nodes 1.6 to 1.8), the hierarchical cascading process is shaped by practical initiatives. In the hierarchical cascading we designed, there is a reflexion on the knowledge that a supply chain view is necessary for obtaining the industry 4.0 values, and that organisations need to first integrate culturally in the industry 4.0 concept, before the supply chain is digitalised, and the implementation needs to be a phased approach (Shao et al. 2021). These postulates are integral part of the architecture we designed in Fig. 1, and are based on the knowledge that the main values of industry 4.0 is in the supply chain (Fatorachian and Kazemi 2021).

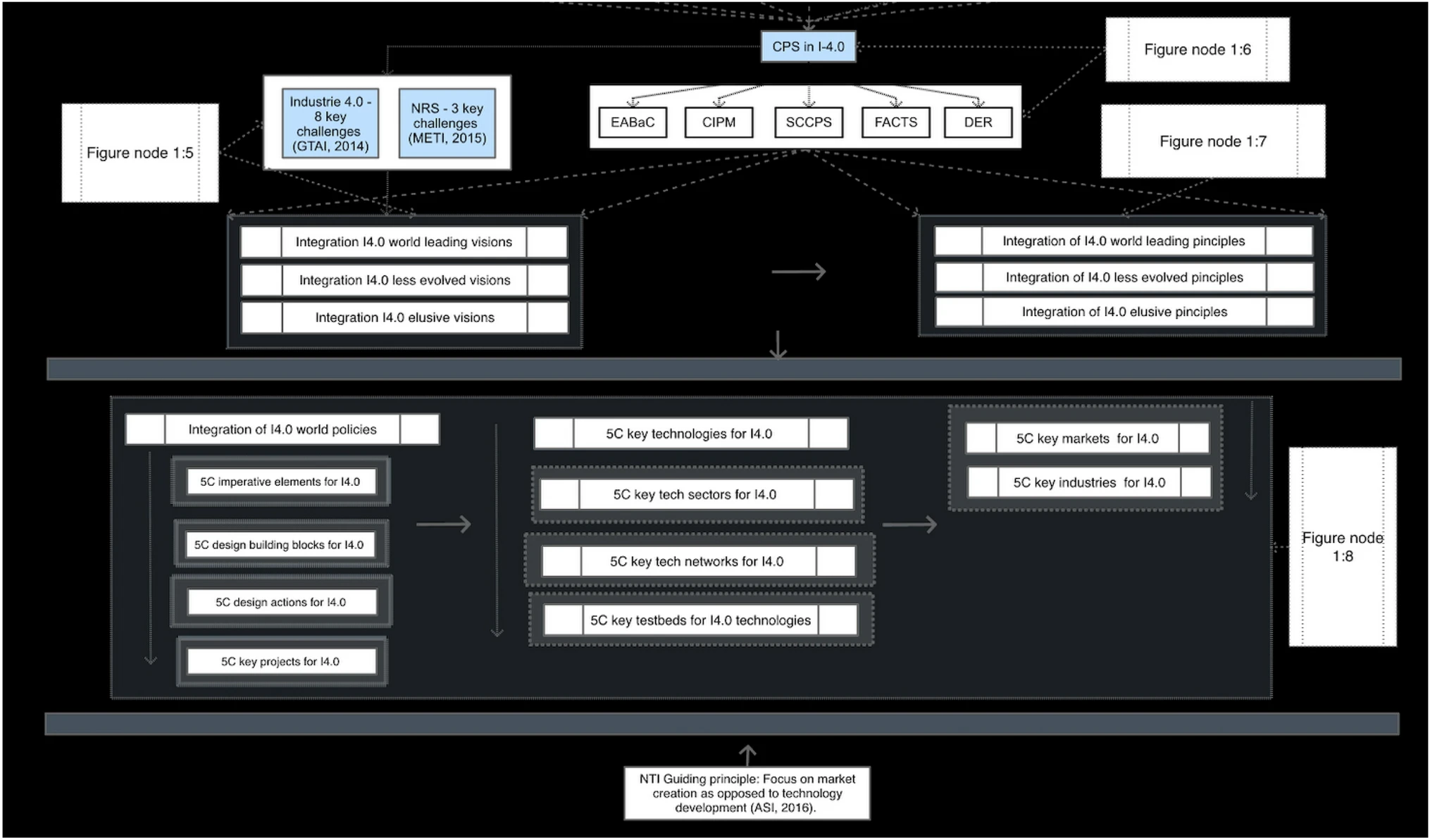

The empirical study builds upon the Figs. 1 and 2 and is presented in Figs. 3, 4, 5, 6, 7, where Fig. 3 analyses the integration aspect (vision and principles) of all practical initiatives in the empirical study (building upon the concept from Figure node 1.5).

Fig.3 Principles for cyber-physical systems in Industry 4.0